Abstract

The Interceptor was created from a desire to have an outlandish piece of gear to increase the stage presence of the band that I’m in, and at the same time recycle some of the harvested parts that I have had sitting around for too long. So the idea was to create a simple tube amplifier capable of driving a 15 inch sub and design a crazy spiral nautilus horn.

The name Interceptor references the ridiculous names given to amplifiers in the 70s, stolen from action movies or cars, many of which I encountered when searching for schematics and basic amp shapes for this project.

Design

The design for the cabinet was very simple, the proportions were designed so the amplifier chassis could sit on a sliding removable board that sat just above the speaker cavity. The top of the amp would continue above to form a shell around the delicate tube amplifier components while also displaying them. The amplifier chassis and components would date back to 50s construction methods and technology, all these parts would be vintage scrap when possible. The standby, breaker, and volume switches were all mounted to this panel, to make sure the amplifier section was totally modular.

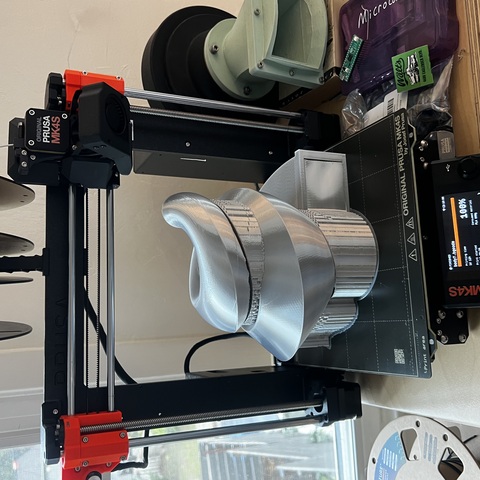

The rest of the design was in the horn. This spiral loft design was designed totally for looks, thought it does significantly amplify the JBL horn driver I scavenged from the dead PA speaker where I found the woofer. The final horn section was modeled after an Altec multicellular horn, and each section of this horn used the complete dimensions of my 3D printer. The horn is mounted directly to the top of the amp with wood screws.

Fabrication

The speaker cab was made quickly, without access to a table saw, so my method was to post process the cab with an edge tracing router, then round over all edges. The final result is dimensionally accurate, and square. The amp was laid out based on other designs I could find online, leaving the HV transformer as far from the audio path as possible. The chassis uses a small wooden frame and 1/8th inch aluminum panel. Tubes are mounted via riveted sockets.

I was missing several high voltage capacitors, so the tube amp section, while mostly in place, was put on hold until those components arrive, and the speakers were driven by a very small 40w solid state amp I placed on the bottom of the aluminum panel. The horn was fabricated in 5 smaller sections that were glued together with CA glue. Removing the supports from within the spiral ended up being a huge pain, so I ended up splitting the center print along a layer line to remove the remaining supports and clean up the inside of the horn. It re-glued relatively well and after primer and paint looks even better.

Conclusions

While I will continue to work on creating a functional tube amp, for a display piece it was perfect and I finished it hours before the performance when I was hoping to use it. Though it is cheating, I did leave the heater winding connected on the tubes so they would glow. The nautilus spiral didn’t sound bad either, it has some bad resonant frequencies with my synthesizer at times, but it overall sounds flat and surprisingly not funky like the shape it is.