Bringing Ideas to Life

A core component of my portfolio is that all of the work presented here I had a majority role in producing. Whether it is a large scale advertising project as an employee, or an ambitious engineering project I design as a challenge for myself, the goal is to pick up a new skill and use the experience to become a better engineer.

This began with the Tom Sachs shop chair, a project I began with no idea how to complete, by the time it was done I had a basic understanding of carpentry that allowed me to begin my role at Event Special Effects, where I would learn everything I needed to rapidly create sturdy wood projects of all kinds. While working as a fabricator for EFX, I learned the basics of CNC operation, and became the de facto welder. Given the volume and scale of projects at this company I became very comfortable with welding MIG, Spool, and even some TIG welding, on projects like the Twisted Tea 16 foot crate. This metal carpentry culminated when an aerospace factory across the street from EFX closed, liquidating a massive machine shop. From this, I became the owner of a small lathe and Bridgeport Mill, which like most things, I committed to, then set out to learn on projects like the Laser Turret, and best demonstrated on projects like 'Big Robot Marcus.'

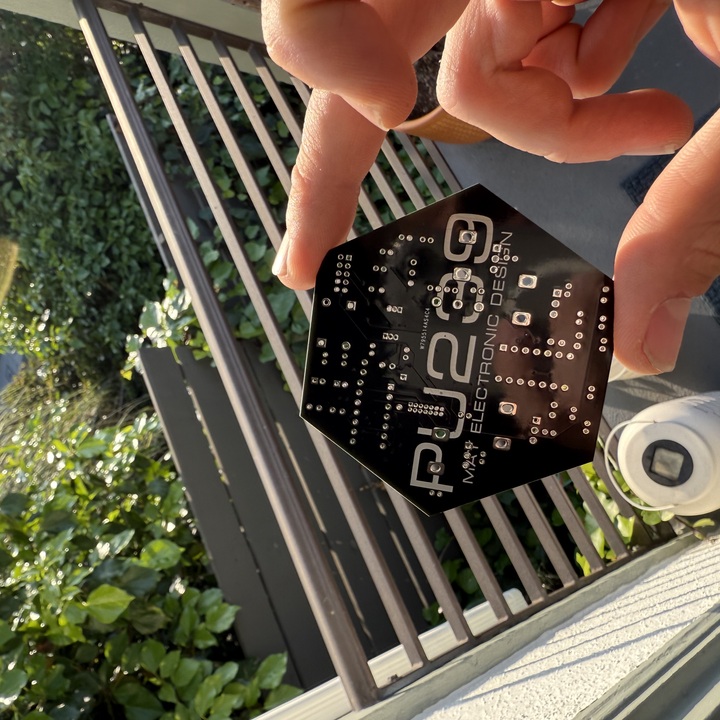

While I was developing all these generalist "maker" skills at my day job, I felt compelled to find something that could become a specialty. My long-term interest in synthesizers and electronics appeared as the daunting answer, though it had been hard all my life to gain knowledge in this field on my own, this difficulty was proof to me that rewarding challenges lay ahead. Initially under the name Mµon Electronics, I began blending my carpentry skills with DIY audio projects and restorations to things like the massively powerful Mµon 1801 THX living room speakers, dim bulb tester unit with isolation transformer, before graduating to complicated troubleshooting projects. One such project and interesting story, is my complete overhaul of a Polymoog 203a. In spring 2025, I changed names to May Electronic Design, where I now have several ongoing projects documented on this site that I could have only dreamed of at the outset of this adventure.

My journey with robotics really began when I bought a surplus CNC machine from the Los Angeles Unified School District for $60. It is an Isel 3020 with an ancient control system totally unusable with the computers I had around. Thus I had to gut, replace and reconfigure the 3 axes of control of the machine. This was an extremely frustrating learning experience, but at the end of it all, I had a small CNC machine in my home shop. This was one experience with steppers, motion control and programming that helped give me a solid basis to confidently enter the world of First Robotics as a mentor. I began my role at the Marlborough School ready to learn the complexities of robotics from my students, as I taught them CNC operation, laser cutting, and 3D printing. One very successful season later, I know how to direct students through the FTC design process, while also helping them to fabricate robots fast and efficiently. Though these are their fabrications projects, thus I set out to create BRM, (Big Robot Marcus) a large-scale FTC robot chassis, that I can use as a completely programmable test platform for automations, autonomous navigation by camera and GPS, as well as accessory and end-effector testing. Marcus illustrates what FTC has taught me as an engineer, and helps me keep the challenges of FTC in perspective. Another point of pride in my robotics journey so far is my series of Mentor-Bot Ant-Weight Battle Bots, that I created to again give myself more of a robotics fabrication experience. These projects highlight fabrication through 3D printing, milling, using the FTC parts library, wire management, iteration, and In-Situ Resource Utilization for fast repairs.